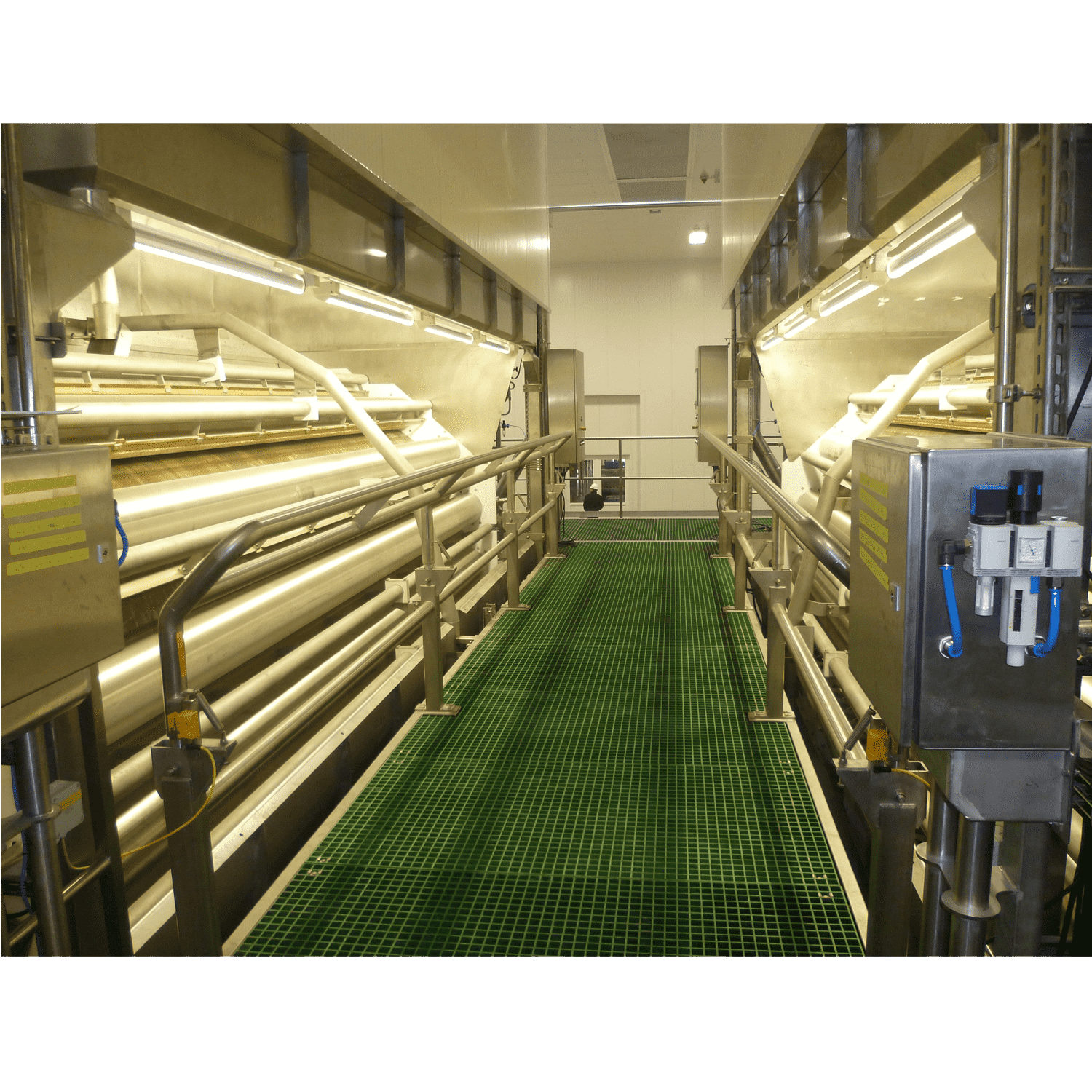

To dry potato mash a thin, perfectly distributed layer of mash is introduced onto a heated cylinder (drum dryer) which evaporates excess moisture. This is followed by the next new layer of mash. The process is repeated until the layer of mash is sufficiently thick. The layer of potato mash is then scraped off and broken into smaller pieces (flakes) by the PreMillSifter attached to the drum dryer.

A lot of steam is released when drying potatoes into flakes. This steam is normally blown outside, resulting in energy loss, odor nuisance and horizon pollution. But this is no longer necessary. By placing the hermetically sealed

E²E SteamClosure over the drum dryers , the released steam is collected and led to the E²E-FlowCondenser. There it is converted into water that can be reused for other purposes.