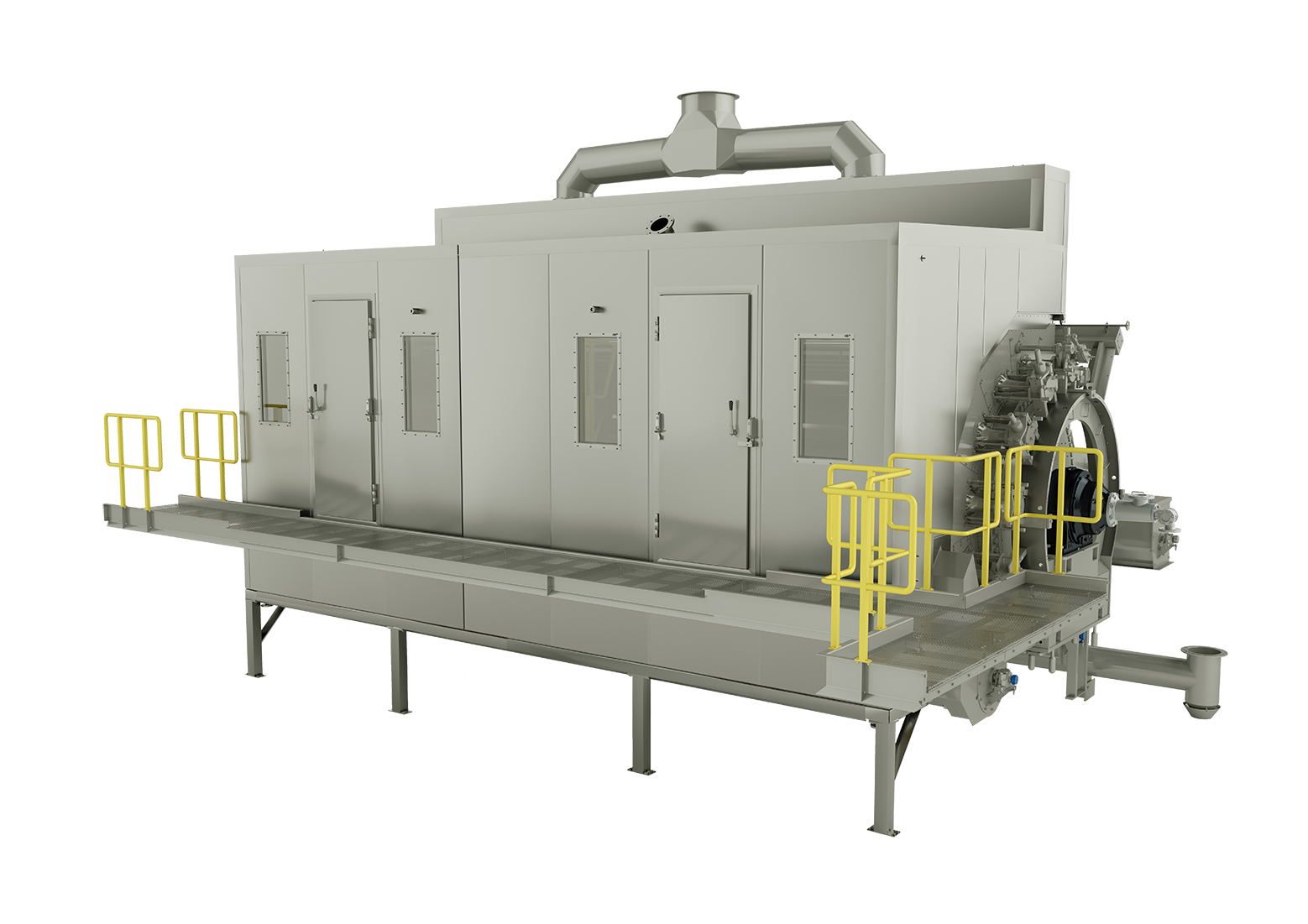

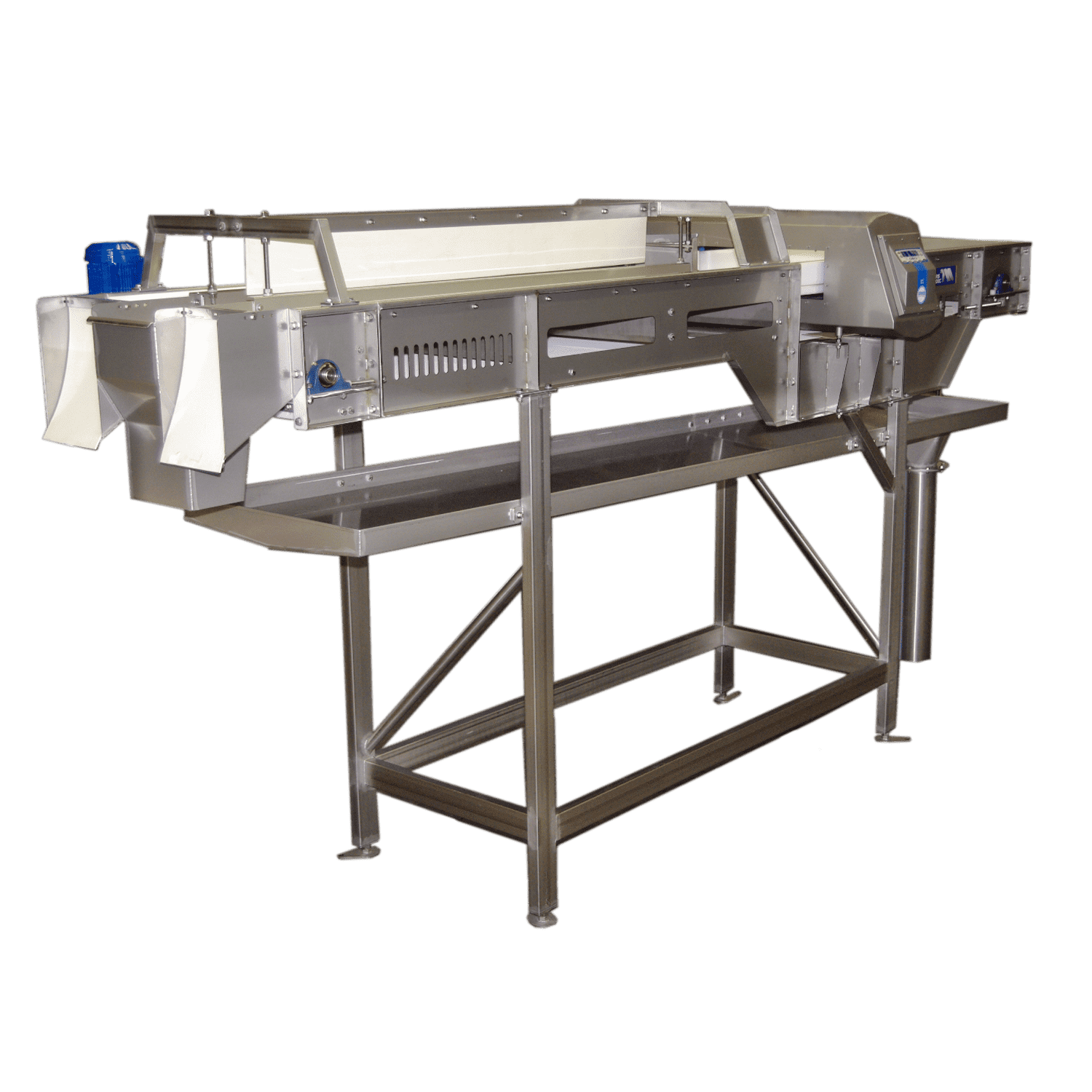

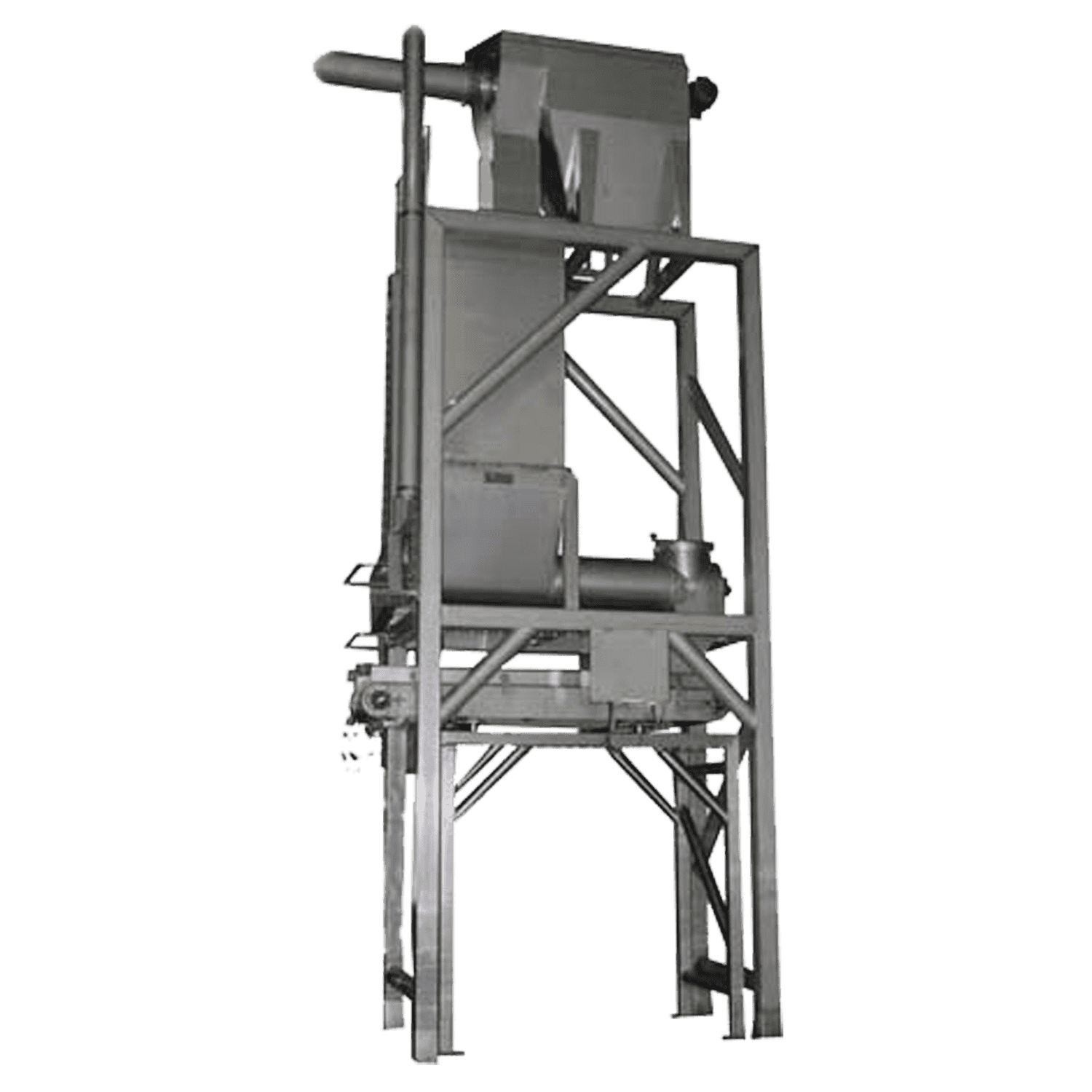

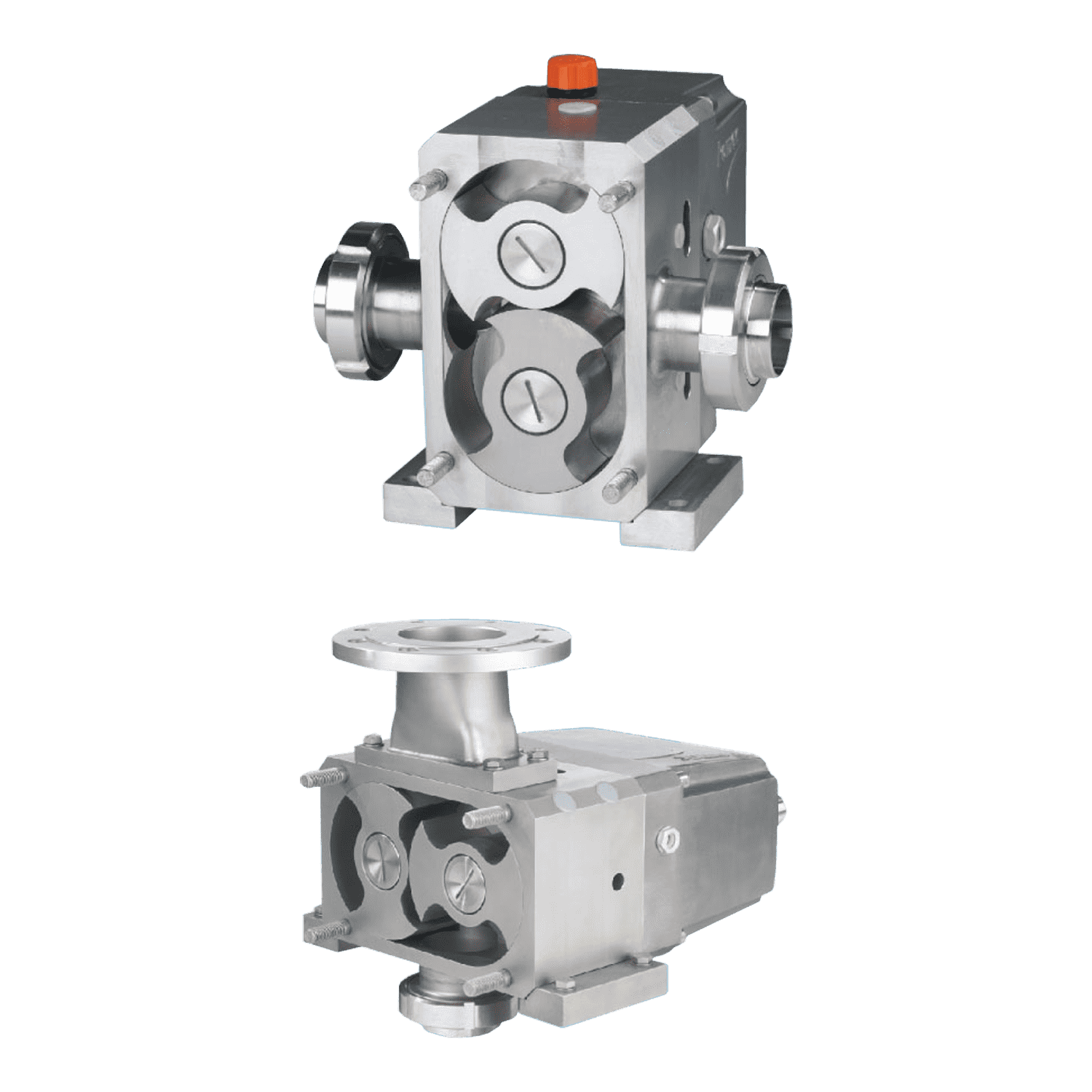

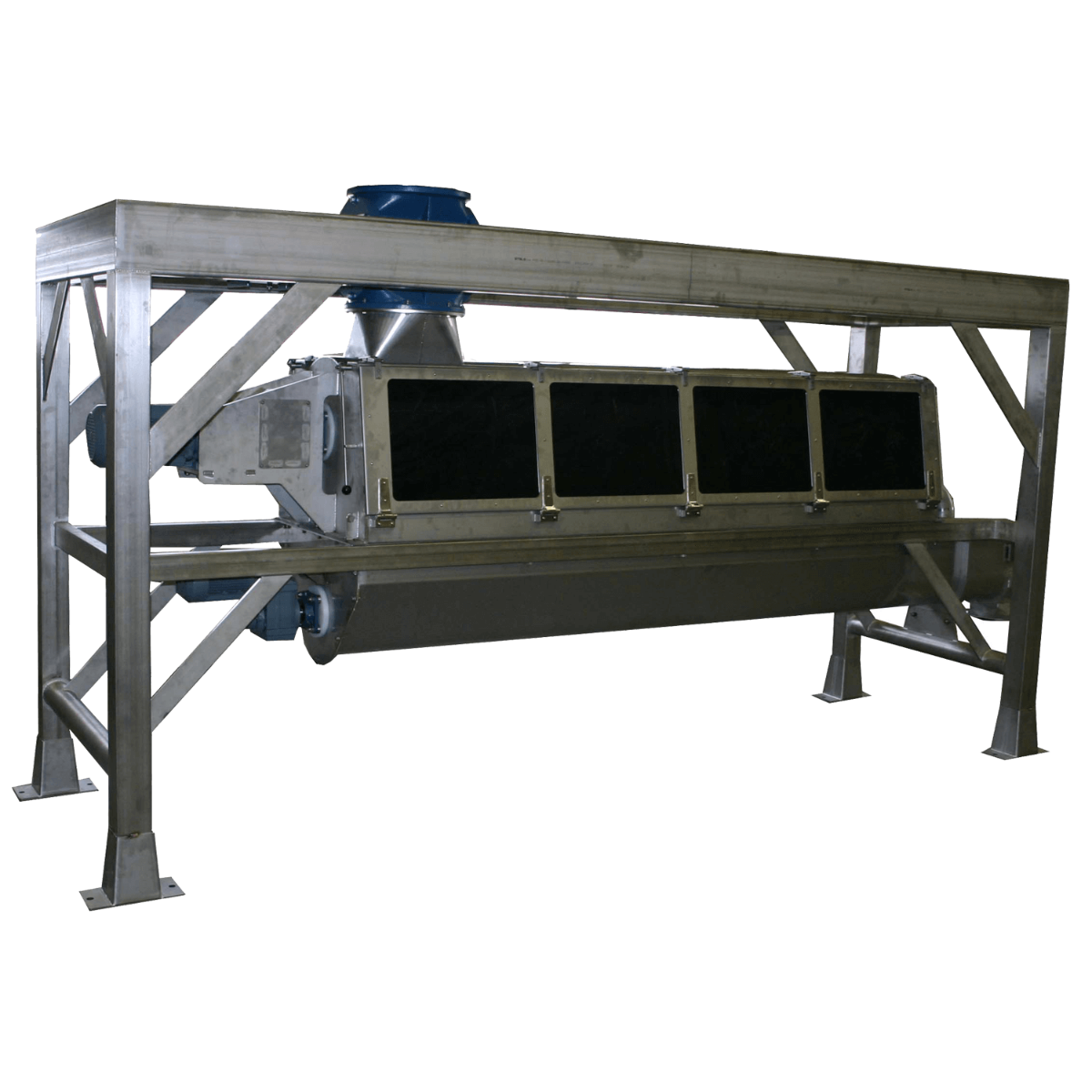

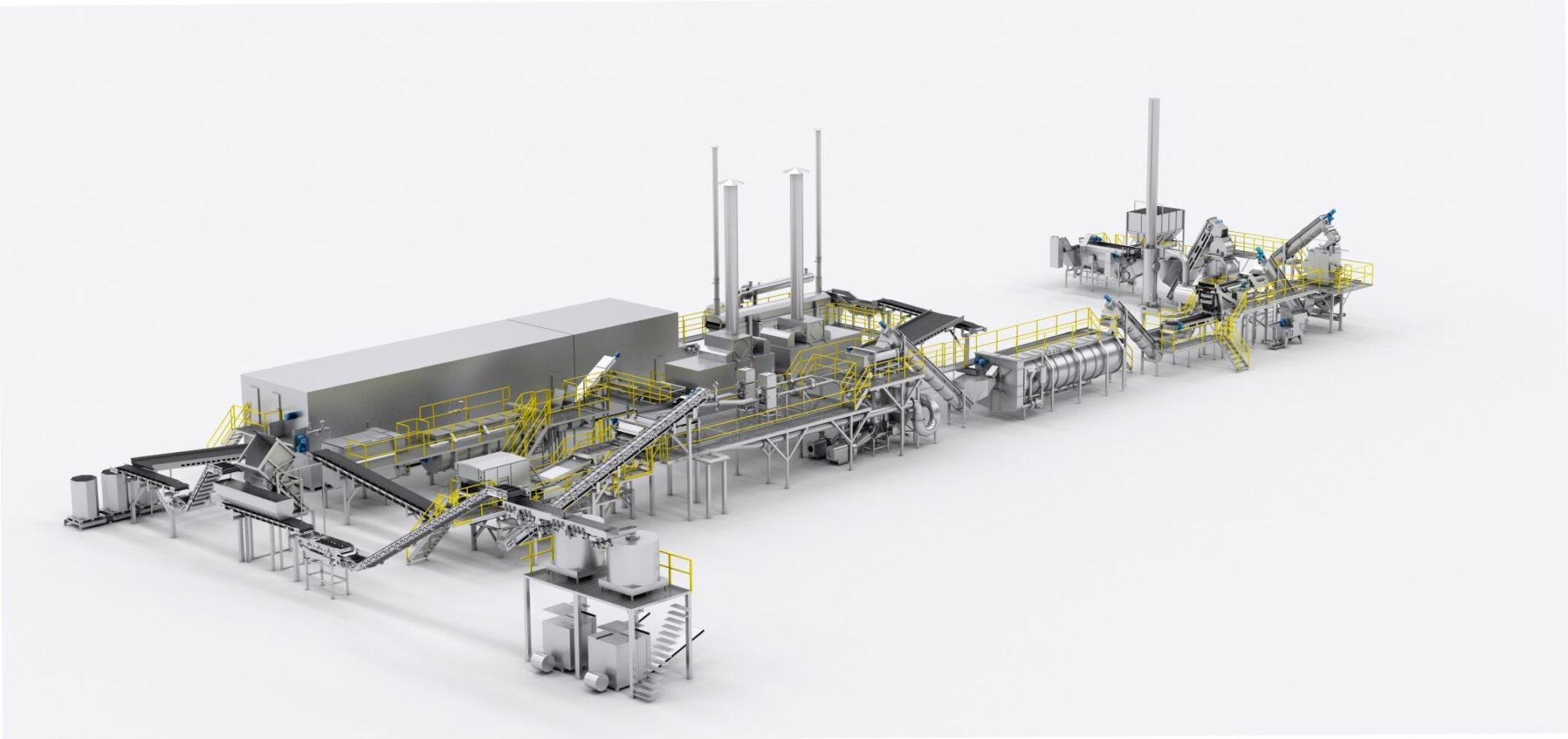

Flake line

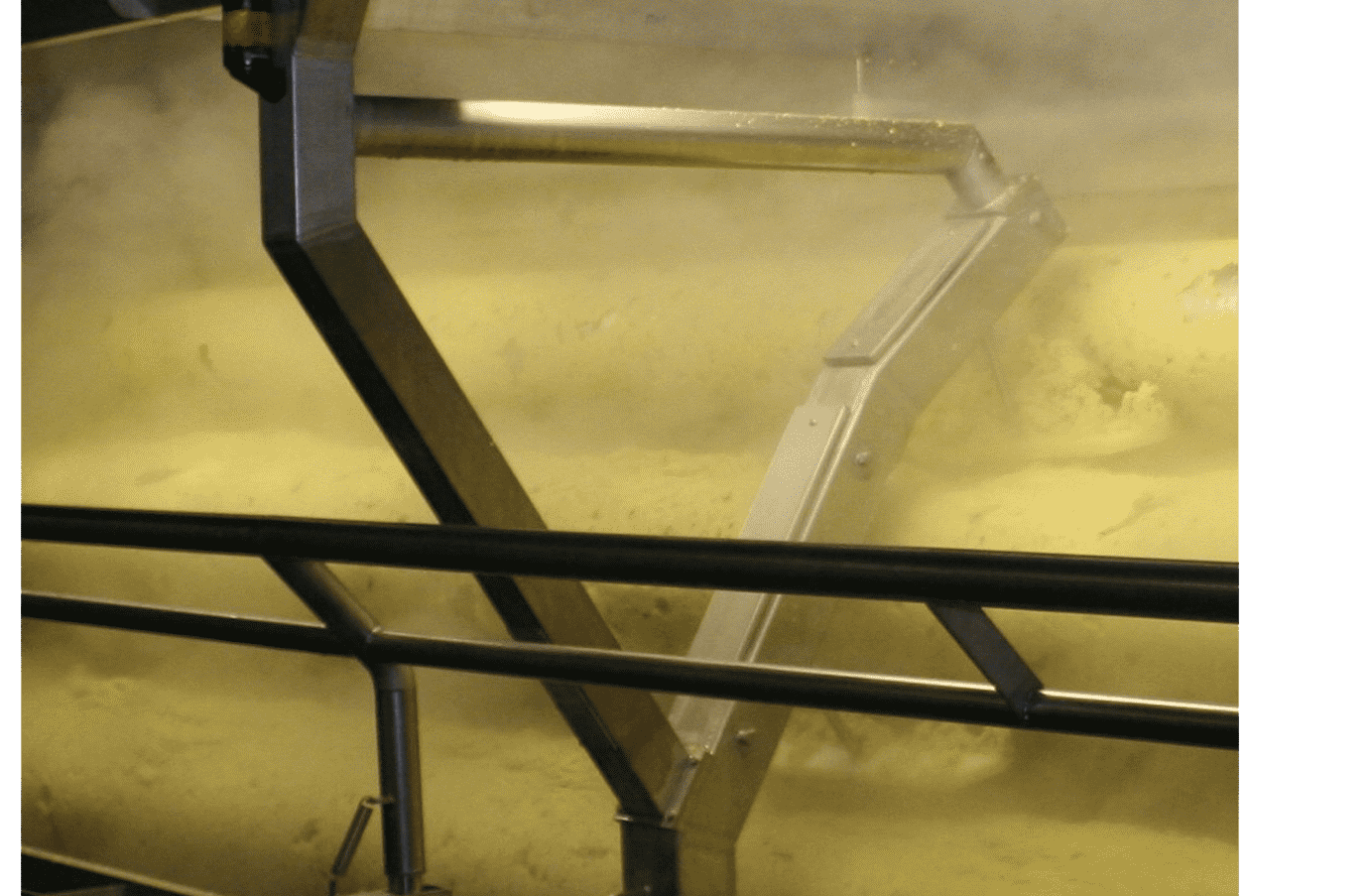

The flake process

Sustainability through innovation

The Tummers flake lines are known for their innovative character in terms of sustainability (raw material consumption, energy consumption, water consumption and waste) and quality (low failure rate, low maintenance and optimum efficiency). Our focus is on improving and making our process lines more sustainable, in order to work together with our customers on a better world.

Turnkey delivery

We can deliver your flake line working from A to Z at your location. After commissioning, we can also train your employees in the operation and maintenance of the installations. Even after delivery, we are always there for you and we offer the best service to ensure that your production process runs as smoothly as possible.