The most efficient way to peel potatoes

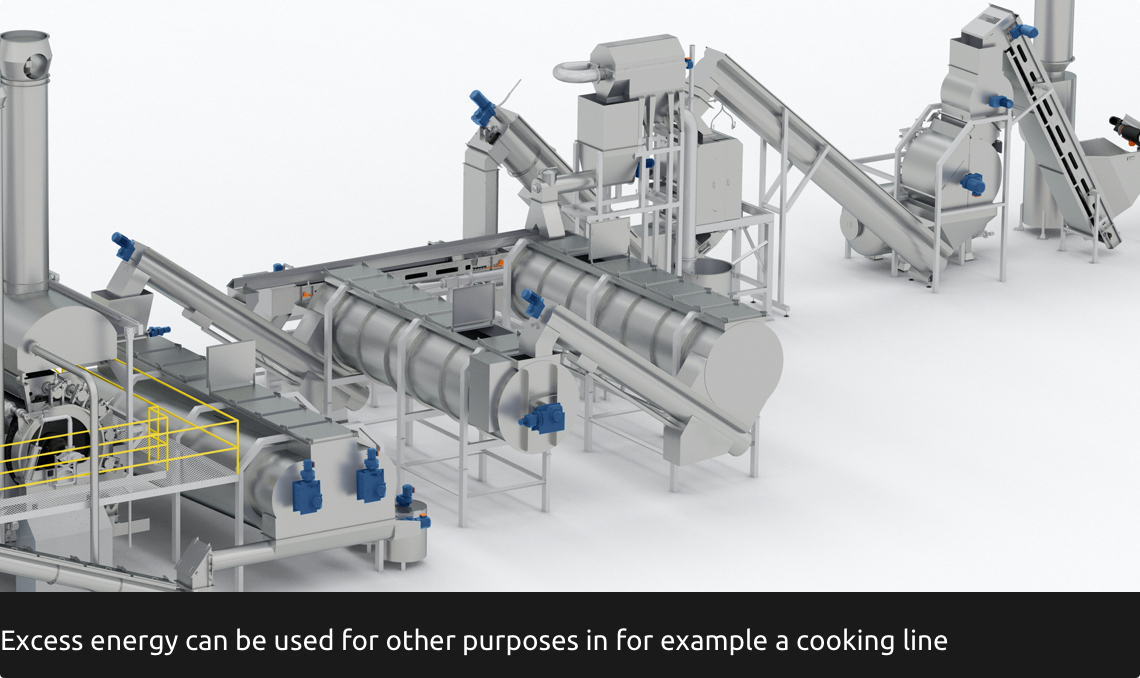

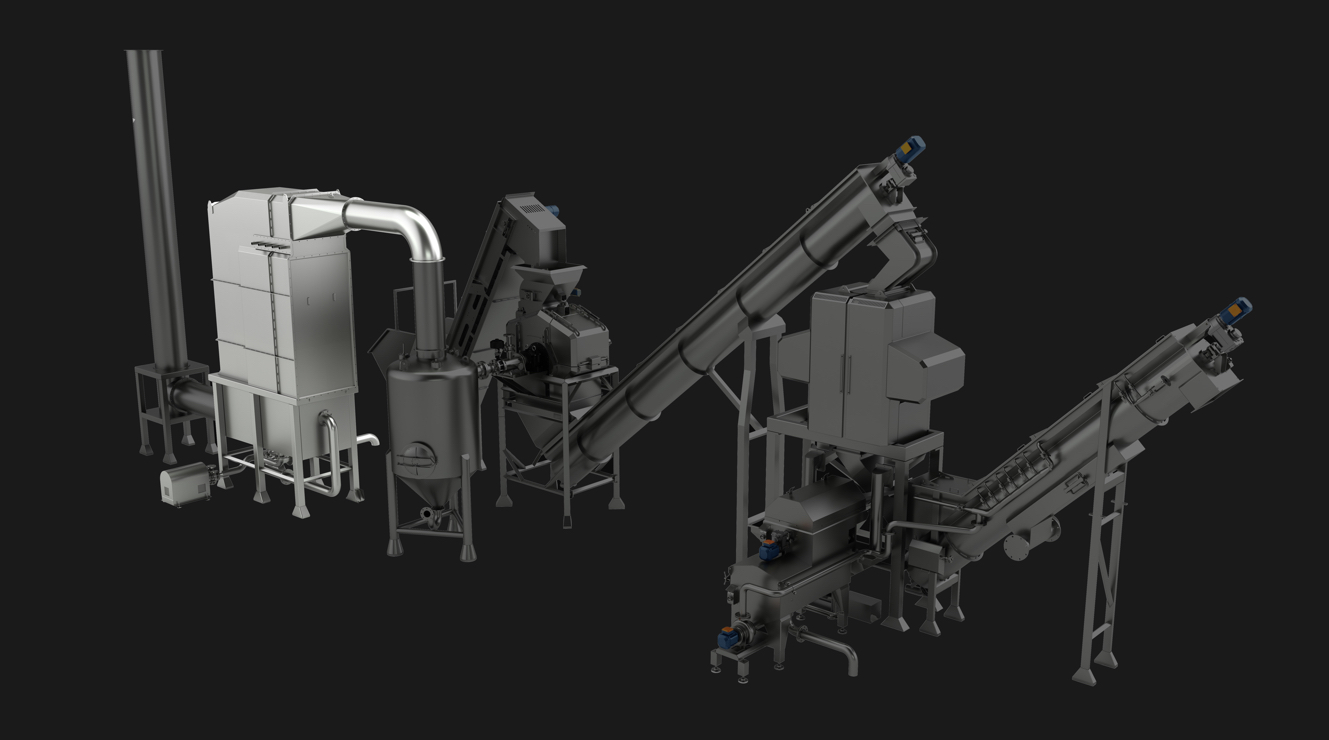

Steam peeling is the most efficient way to peel potatoes, but its emission also causes lots of noise, a smelly steam cloud and loss of energy. Our newest innovation -the so called ‘E²E-Condenser’- puts an end to the emission of steam peeling and in addition saves costs and energy. The ‘E2E’ therefore stands for ‘emission-to-energy’.